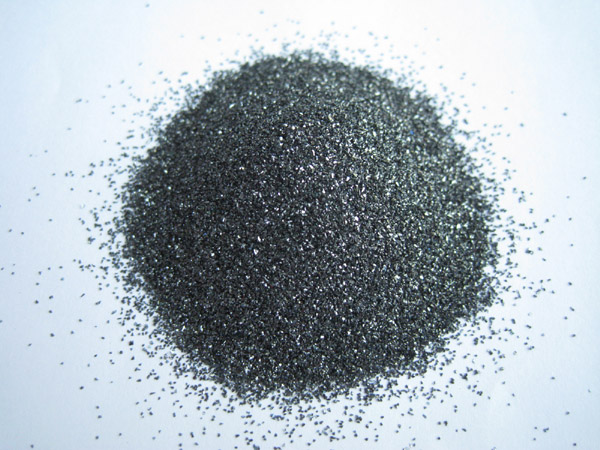

Silicon Carbide

Peformance:SIC is made from quartz sand and petroleum coke(smokeless acetylene) (salt added in the produce of green silicon carbide) as the mainraw material.it is made via light resistance from hydrometallurgical,it is black opaque body hexagonal crystal and MOHS -hardness in the 915-9.5,which is after diamond and boron carbide with crisp and sharp performance and certain degree of conductive heat

Silicon carbide have two color ,black silicon carbide is higher toughness than green silicon carbide with sic purity 98%,it have been used for processing glass,ceramic,stone, refractory materials ,cast iron and other metal. Green silicon ’s purity can reach to 99%, With higher purity of crystallization and hardness, abrasive tools made of it are suitable for processing hard and brittle materials such as: hard alloy, titanium alloy, bearing steel,non-ferrous metals like copper, brass, as well as some non-metallic materials including: glass, agate, electrical ceramic, quartz products, rock, gem, ceramics and so on.

Usage:

1.Sic processed by low-intensity metal and non metallic and also can be used in fire-resisting materials and the electronic industry

2.Colored metal .iron and steel industy .constructing materials and ceramic .Energy-saving

3.Usage:It is the important raw materials of high refractories manufacturing ,high-temperature ceramics,body heat resistance, abrasives and recrystallized silicon carbide.

Used for abrasives ,lapping, Polishing

|

properties

Type

|

ABRASIVE GRADE

|

|

GRIT

|

8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220#

|

|

“FEPA”

|

F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000

|

|

“JIS”

|

240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000#

|

|

Guarantee Value

|

Typical Value

|

|

Chemical

Composition

|

SIC

|

≥98

|

98.5

|

|

F.C

|

≤0.3

|

0.2

|

|

Fe2O3

|

≤0.2

|

0.15

|

|

H2O3

|

≤1

|

0.3

|

|

|

|

|

|

|