Fused

Ceramic Sand

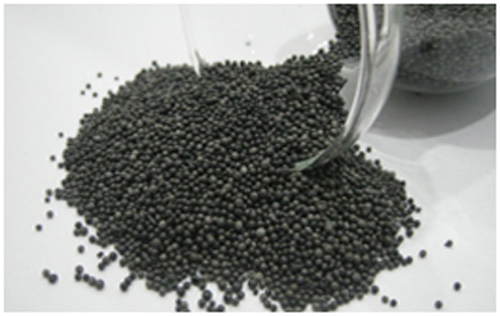

Ceramic foundry sand called China

Cerabeads, ceramsite sand ,china Cerabeads and cerasand too, is made from

high quality bauxite, by re-fused and blown to ball type. With advantage of

fine surface smooth finish and air permeability, it is a new type casting

material for precision casting, coated sand and self hardening sand etc.

Chemical data

|

Al2O3

|

70-85%

|

|

|

SiO2

|

5-15%

|

|

|

Fe2O3

|

5%max

|

|

|

TiO2

|

5%max

|

|

|

MgO

|

0.5%max

|

|

|

K2O

|

0.5%max

|

|

|

CaO

|

0.5%max

|

|

|

|

Physical

|

Grain shape

|

Perfect round ball

shape

|

Loose Bulk Density

|

1.9 – 2.1 g/cm3

|

|

Color

|

Brown-Black

|

Refractoriness

|

2050℃

|

|

Angle index

|

1 .1 max

|

Liner thermal expansion

|

(200℃ - 1000℃)

5×10-6/℃

|

|

Size rang

|

0.053-3.36mm

|

|

|

Application

|

1

|

Widely used in foundry technique like resin-bonded sand, sodium silicate sand, and clay- bonded sand for sand core and casting mould making

|

|

2

|

Replace chromite sand and widely used in sand core making like jacket core, oil duct core, tappet core of engine.

|

|

3

|

Replace chromite sand for steel casting facing sand and sub-layer of molding sand (backing sand).

|

|

4

|

Widely used as dry sand and sand box for EPC process and V method of casting processes.

|

|

5

|

Widely used as the main raw materials of advanced refractory products (Ladle drainage sand,gravity casting material, casting coating, etc.).

|

|

6

|

Widely used as cleaning sand for copper and aluminum alloy castings

|